clgodwin79

Go Kart Champion

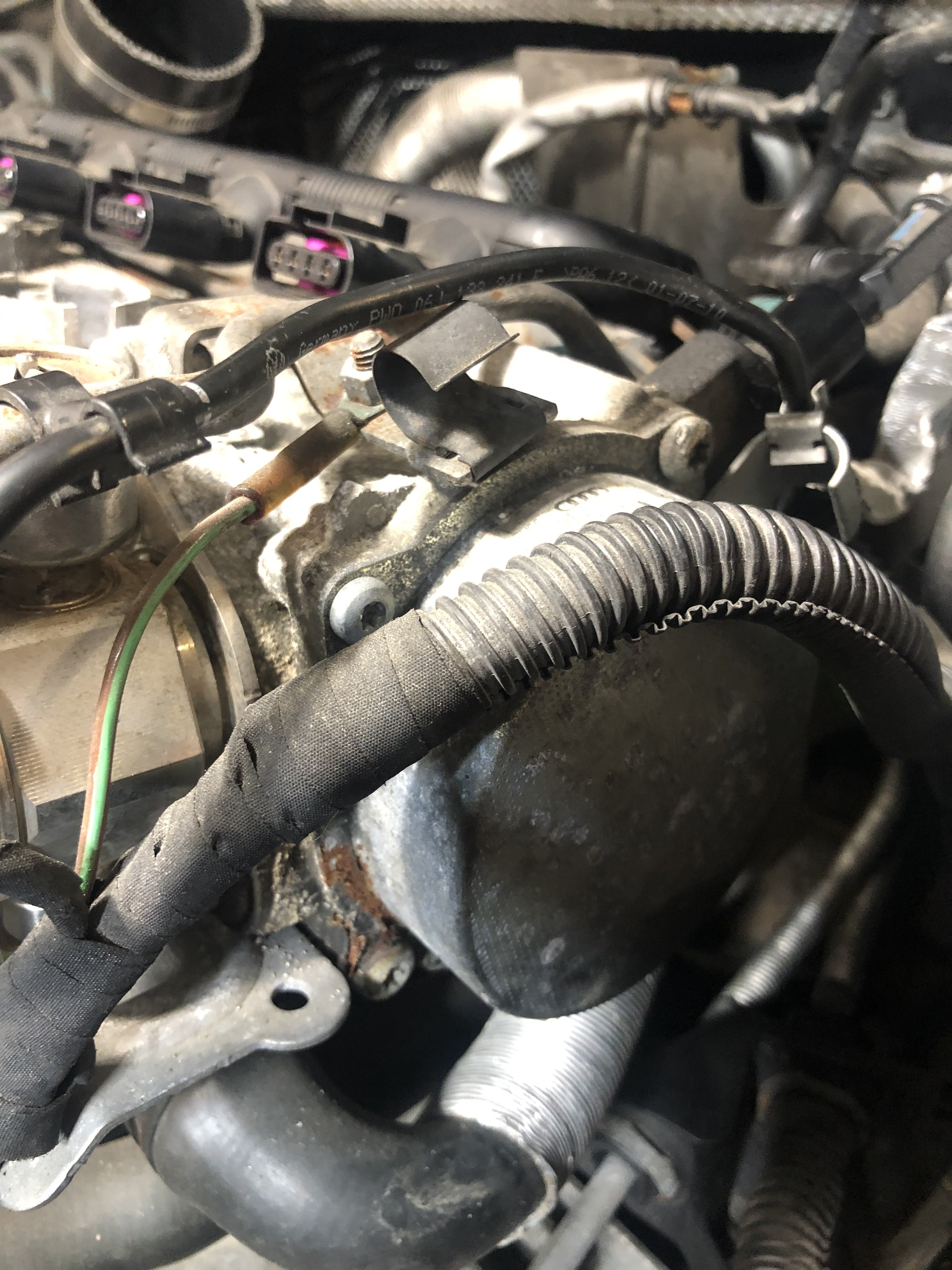

What’s this called?

It connects to the non chain side of the exhaust cam.

I guess I’ll probably just do the $200 and get 3 VINs. I’ll worry about more later since I currently only own the 1 car.

So chain stretch reset and throttle body relearn and that’s the only specific things I should need to address?

It connects to the non chain side of the exhaust cam.

I also ordered my USB VCDS Ross-Tech tool so I can do my TB alignment. And everything I read says that you can monitor timing chain stretch with it, but is there some kind of reset or relearn process that I’ll need to do since it’ll be all new chains and tensioners.TB has an alignment process that must be done through VCDS. Plus reading chain stretch and timing, etc. It's a valuable and worthwhile investment.

Best bet is to get a cable from Ross-Tech, knock off brands are dodgy. You can get a limited VIN version if you want to save money now and then sell it to someone else if you want to upgrade later or Ross-Tech has an upgrade program.

https://store.ross-tech.com/shop/vchv2_ent/

The wireless version is nice to be able to do some stuff on the phone app but it's no where near the same as the full version on a laptop. Definitely a "cool feature" and not a necessary one you can't live without.

Another thought that would had was that maybe it was running a little rich because of the Cobb stage 1 tune or Cobb intake maybe? Oh well, once I have it running I’ll just see what VCDS tells me.Finally!! I got the head off. Definitely a 2 man job. That turbo makes it just slightly too heavy to safely put on or take off by yourself.

View attachment 203766View attachment 203767View attachment 203768View attachment 203769

If you look you can see a few things. First of all every single intake valve is bent and stuck open. Which I could already tell just from looking in through the intake side of the head before I removed it. And you can definitely see on the valves and the pistons where they hit each other because it knocked a LOT of carbon loose. Which brings me to my next thing that sticks out. There’s an insane amount of carbon build up even on the tops of the cylinder walls. Like it’s loose little crusty pieces everywhere. So I’ll definitely be vacuuming and cleaning those up with WD40. But other than that there’s no damage to the pistons themselves or the cylinder walls thankfully.

View attachment 203770View attachment 203771View attachment 203772View attachment 203773

Any suggestions or ideas for easy ways to get the 2 broken down pipe turbo studs out? I have already sprayed both sides of all of the studs with penetrating fluid. I plan to use the 2 bolts butted against each other trick to remove the ones that aren’t broken.

View attachment 203774

I also ordered my USB VCDS Ross-Tech tool so I can do my TB alignment. And everything I read says that you can monitor timing chain stretch with it, but is there some kind of reset or relearn process that I’ll need to do since it’ll be all new chains and tensioners.

Another thought that would had was that maybe it was running a little rich because of the Cobb stage 1 tune or Cobb intake maybe? Oh well, once I have it running I’ll just see what VCDS tells me.

Soak them in rust penetrant, fire/torch to heat them up, stud remover. If that doesn't work, weld a nut to it.Finally!! I got the head off. Definitely a 2 man job. That turbo makes it just slightly too heavy to safely put on or take off by yourself.

Any suggestions or ideas for easy ways to get the 2 broken down pipe turbo studs out? I have already sprayed both sides of all of the studs with penetrating fluid. I plan to use the 2 bolts butted against each other trick to remove the ones that aren’t broken.

This is the route I decided to go. Been sprayed several times in the last day with penetrant and I got a stud remover from Advance Auto this morning. Gonna try heating them up in a bit and see how it goes. Thanks for the invite info!Soak them in rust penetrant, fire/torch to heat them up, stud remover. If that doesn't work, weld a nut to it.

And yes, there’s a brand new union between the oil cooler and water pump with brand new O rings.View attachment 205599

Next I decided to tackle the water pump since it’s never going to be easier to get to than it is now. This was with the pump removed. You can see where a combination of coolant and oil has leaked down over the years and has the black paint from the block coming off pretty badly on the area under the water pump. This thing had all kinds of leaks!

View attachment 205600

This is just a side by side comparison of the old plastic water pump next to the new aluminum one.

View attachment 205601

View attachment 205602

In these pics I’m trying to show you where are why my old water pump cracked at the top. Apparently my cam cover had been leaking oil down onto the top mating surface of where my water pump sits on the engine block. Over time, the oil penetrates into the rubber gasket and causes it to swell and take up significantly more space, which led to cracking the top area of the water pump. This is another reason that an aluminum water pump is the way to go in my opinion. Hopefully it’ll be a very long time before my cam cover leaks again, if ever. But if it does, the aluminum is a lot stronger than plastic so the seal may eventually still fail, but no stupid plastic housing will be there to crack.

View attachment 205603

And here it is torqued to it’s 9 nm spec. It definitely looks a lot better than the plastic in my opinion! Not that you’re going to be able to see much of it when it’s all back together.

I thought about cleaning up the exhaust manifold and turbo really well and painting them with some of the high heat exhaust and header style paint but decided against it. For one, you literally never see any of this. And for 2, it is just surface rust from extreme temperatures, but the actual steel is stupid thick. It would probably have to rust for 100 years to ever be a problem or to have to worry about it rusting through. So it’s going to have to live the rest of it’s life the way that it is and I’m 100% Ok with that even with my next level OCD about doing things the right way.Also, as much as I hate to admit it, I tapped out and outsourced one small, but very important thing.

The turbo down pipe exhaust studs. If you remember, 2 of the 4 broke when trying to remove them. I went to Advance Auto and got a stud extractor. I was all excited and happy and was just sure that it was going to work. I had sprayed Deep Creep penetrant on them countless times over many many days. So I got my little camping propane torch out, which is all I have and heated one up as much as possible and started torquing on one of the non broken studs. And it F’ing snapped! Of course it did! Why wouldn’t it have?!?!

So I decided to try and cut my losses and try my hand at drilling them out, only to realize that I was nowhere near the middle of the stud and the only way to have gotten there would have been to use a cut off wheel to get it flat so I could punch a tiny indention in the middle and slowly work my way up in drill bits. But because of the shape of the exhaust manifold there was no good way to hold it where I could secure it upright for me to drill out. But then I started thinking about how long it would take and how valuable my time is to me and said screw it. So I called around and no machine shops wanted to mess with it but referred me to a guy who works at a local hole in the wall auto repair place. He quoted me his hourly labor rate of $88 and asked if I wanted him to do all 4 or just the 3 broken ones. Murphy’s Law along with my bad luck will screw me 100% of the time and I didn’t want to get the head back on and go to torque the 4 exhaust nuts down only to have that one break and either deal with an exhaust leak or have to pull the head again and then get new head bolts since they’re 1 time use along with a new head gasket and countless wasted hours. So I opted to have him do all 4. I wasn’t in a huge rush anyway since I was dealing with my dad’s funeral stuff, so I had time to wait.

So, in the end, he said that he welded nuts onto them and heated them up a lot and was able to get all 4 out that way. Which I can tell is true by to few small pieces of slag that I had to scrape off of the flange area. He claimed that it took him 4.5 hours, but only charged me for 3.5 since it took him like a week before he even started working on it. So, when it was all said and done, it was a fairly expensive $308 out the door. But I was happy to pay it and not have to deal with what was honestly outside of my wheelhouse to have done correctly!

View attachment 205605

So here are my very overpriced newly installed exhaust studs!!

Now I have have to reattach it to my new head with all new gaskets on everything and I’ll be ready to put it back onto my engine block after cleaning the top of the block and cylinders one last time.