torga

Autocross Champion

This past Friday I mostly installed a NewSouth boost gauge, but had to leave the manifold end unconnected due to the too-thick o-ring included with my Torque Solutions boost tap. I measured the o-ring and it was an exact match for a Parker 2-117 o-ring. The only other thinner o-ring in the Parker catalog is the 2-020, with a thickness of 0.070" (vs. the 0.103" thickness of the 2-117 o-ring. I waited until Monday to source a 2-020 o-ring from a local supplier.

That morning I installed the thinner o-ring, fired the car up, and immediately was reading about 20-22 inHg of steady vacuum. Beautiful. I did a couple of test pulls on my to work and I read between 15-17 psi of peak boost.

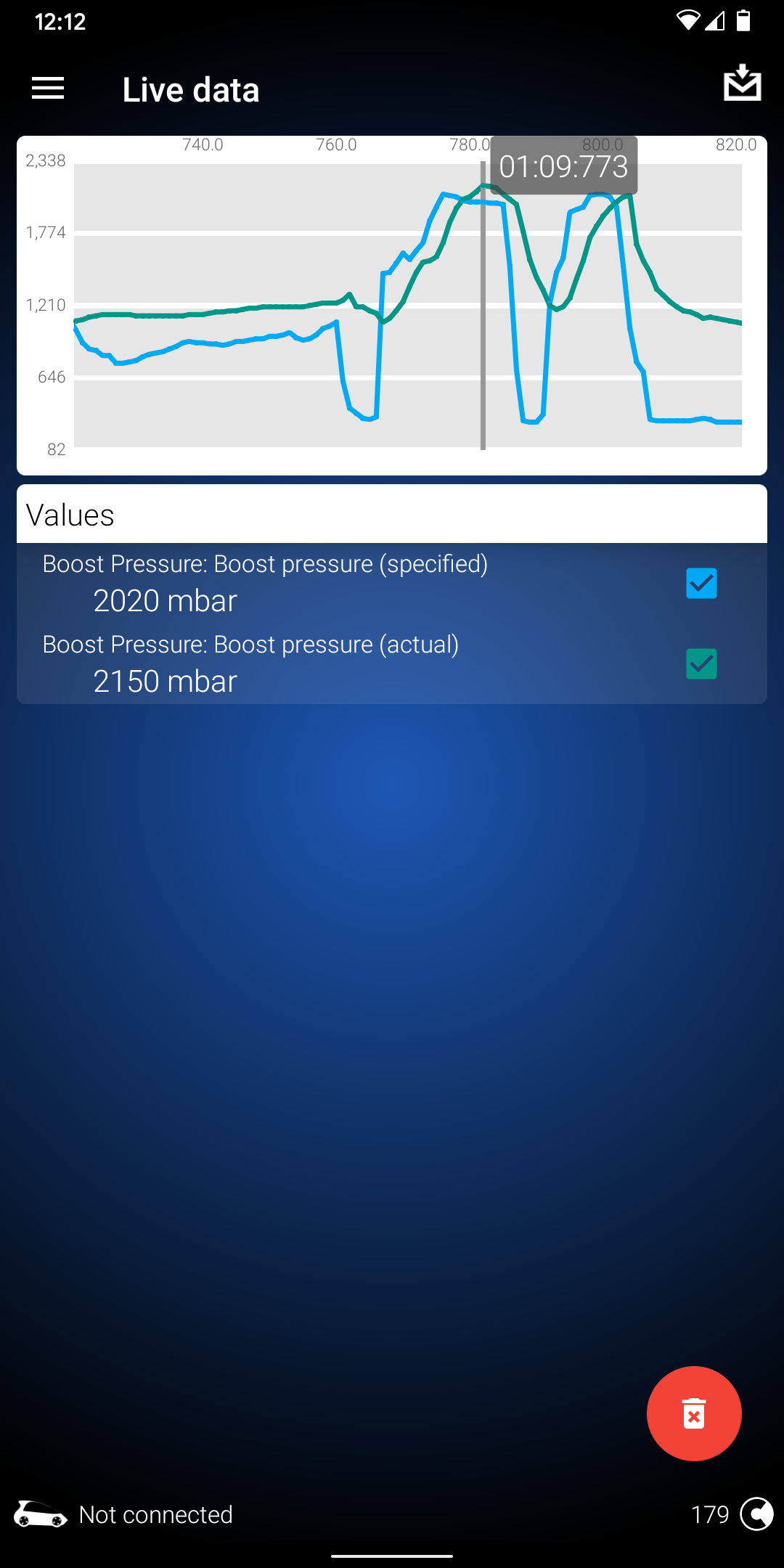

On my way to work today, I charted requested boost vs. actual boost with OBDeleven to make sure the thinner o-ring was sealing correctly, and all the values matched right up -- no discrepancy between requested and actual, and the needle reasonably matched both of the values.

I ended up ordering a small quantity of metric o-rings out of curiosity, specifically M2x22, to see if I'm still able to install the boost tap. This o-ring is slightly thicker that the Parker 2-020 that went in; this is to hopefully get an even better seal, since withstanding K03 boost doesn't necessarily mean it'll withstand K04 boost -- just curious about a more robust solution. Either way, no hiccups and no leaks so far!

Bonus shot of the gauges all lit up, really gotta give it up to NewSouth for matching the OEM gauges almost perfectly! Great addition.

That morning I installed the thinner o-ring, fired the car up, and immediately was reading about 20-22 inHg of steady vacuum. Beautiful. I did a couple of test pulls on my to work and I read between 15-17 psi of peak boost.

On my way to work today, I charted requested boost vs. actual boost with OBDeleven to make sure the thinner o-ring was sealing correctly, and all the values matched right up -- no discrepancy between requested and actual, and the needle reasonably matched both of the values.

I ended up ordering a small quantity of metric o-rings out of curiosity, specifically M2x22, to see if I'm still able to install the boost tap. This o-ring is slightly thicker that the Parker 2-020 that went in; this is to hopefully get an even better seal, since withstanding K03 boost doesn't necessarily mean it'll withstand K04 boost -- just curious about a more robust solution. Either way, no hiccups and no leaks so far!

Bonus shot of the gauges all lit up, really gotta give it up to NewSouth for matching the OEM gauges almost perfectly! Great addition.