grambles423

Automotive Engineer

Figured another DIY would help.

Another good reference, but its an FSI engine: http://www.stasisengineering.com/si...l_pdfs/STaSIS MTF turbo install Mk V rev9.pdf

TOOLS NEEDED

Another good reference, but its an FSI engine: http://www.stasisengineering.com/si...l_pdfs/STaSIS MTF turbo install Mk V rev9.pdf

TOOLS NEEDED

Prep Work

- Jack the Car Up: Not too high or otherwise you will not establish a good ergonomic standard and will experience back pain, etc. etc.

- Remove Engine Cover

- Drain Oil (ONLY if you need to. I was up for a service at this point so I went ahead and did it. Go ahead and swap filters too)

- Remove Passenger Front Wheel: I went ahead and just removed both

- Remove the Intake: I cannot give accurate pictures of the stock uninstall because I purchased the vehicle with a BSH stage 1 and 2.

- Remove Passenger Splash Shield (T25): Make sure you bag these up and label them.

- Remove Heat Shield

- Remove (6mm Allen) Plug located towards the bottom driver’s side. I used a regular Allen key with a 6mm socket screwdriver attachment as a breaker bar

- Remove (2 x M10 XZN) Bolts holding heat shield to block (Seems that some MK6's have a 6mm Allen for these)

- Remove (M8 XZN) bolt on top of heat shield that holds various lines and intake tubing mount. (Watch out, there is a nut underneath [Some MK6's have this nut welded on])

- Remove (2 x T30) bolts holding the multiple lines to the block. One is located on the driver’s side by the fuel pump and the other by the turbo inlet on the block.

- Unclip Vaccum line and remove from block

- Move lines up and away from the heat shield onto the top of the block. I used a zip tie to hold these back. Remove Heat Shield

- Remove (6mm Allen) Plug located towards the bottom driver’s side. I used a regular Allen key with a 6mm socket screwdriver attachment as a breaker bar

- Remove Downpipe (Honestly, you dont really have to remove the entire thing, just the first portion of the flex pipe: Seeing as though there are many threads for this, I will still include the steps. Please refer to this thread made by Plac: http://www.golfmk6.com/forums/showthread.php?t=25392

- Remove Passenger Side underbody tray (T25)

- Pull O2 Sensor off of underbody stud bracket

- Unplug Harness from bracket (This will help later for uninstall/install)

- Remove Cross Member support brackets (13mm)

- Loosen Sleeve Clamp to CBE (16mm)

- Remove CV Heat Shield (16mm open end)

- Remove DP Flange Nuts: Tricky, but doable. (16mm and PB Blaster) However, your kit includes studs and nuts, so you shouldn’t have to worry about ease of uninstall

- Remove Downpipe Bracket (13mm)

- Remove DP

- Swap O2 Sensors at this time to your new OEM DP (Or not, if you’re using stock hardware) (22mm or 7/8” Combination Wrench)

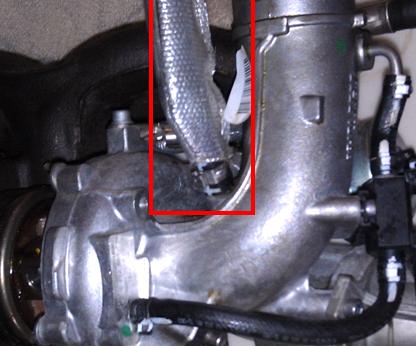

- Remove Pancake Pipe (2 x T30) Undo Hose Clamps and the two bolts holding it to the block

- Disconnect DV and N75 Connectors. Its best to push IN the connector then pull the tab, that way the pressure can be lifted off the tab.

- Cover Front Sub-frame with towel. I managed to drop a few washers and tool bits in there and had to fish them out with my magnetic hook. Pain in the ass.

Time: 2.25 Hours

Last edited: