Meet Abbi. Don’t mess with her.

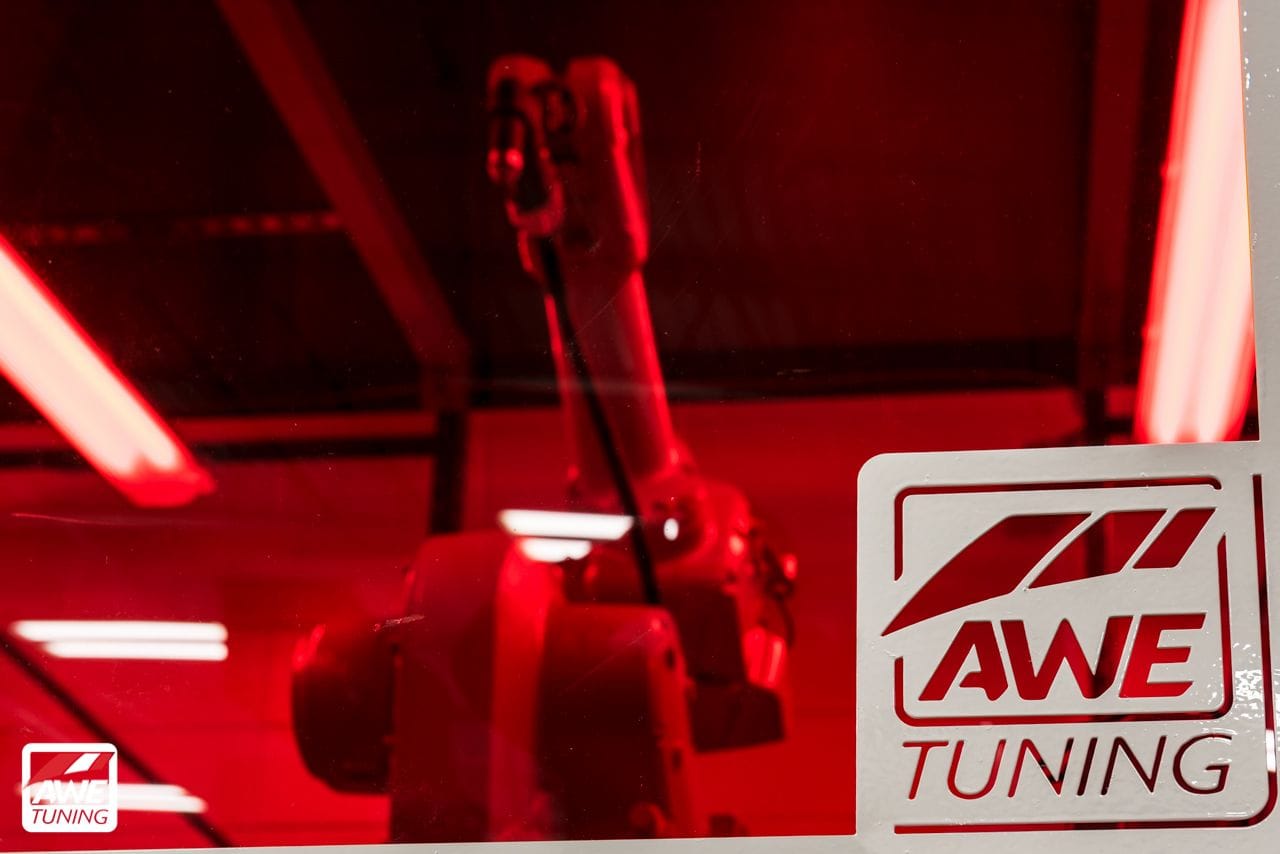

Allow me to introduce AWE Tuning’s newest workhorse -- the AWE Tuning ABB IRB 1600... and we’ve affectionately dubbed her, “Abbi” (pronounced like Abby).

We’re about speed, accuracy, quality and efficiency. While not taking away from the handcrafted nature of AWE Tuning exhausts, it was time to cut out some cutting. It was time to recruit a robot.

Cue the ABB IRB 1600 -- a 250kg robot with a 6kg payload, devoted to high performance. Very appropriate.

Why ABB? Why Abbi?

- ABB is the authority in automation technology for many reasons, but here’s why they were the go-to for us:

- ABB has the most advanced control software out of all major robotic competitors (the actual controller itself is a gamer’s paradise!).

- Abbi’s path and motion control, and accuracy -- which is critical for cutting -- is the best in the industry. All robots can go point-to-point accurately, but ours can travel between those points better than any other brand of robot.

- A gearbox for each axis instead of belts and/or harmonic drives allows for very high acceleration rate and velocity.

What it means for you:

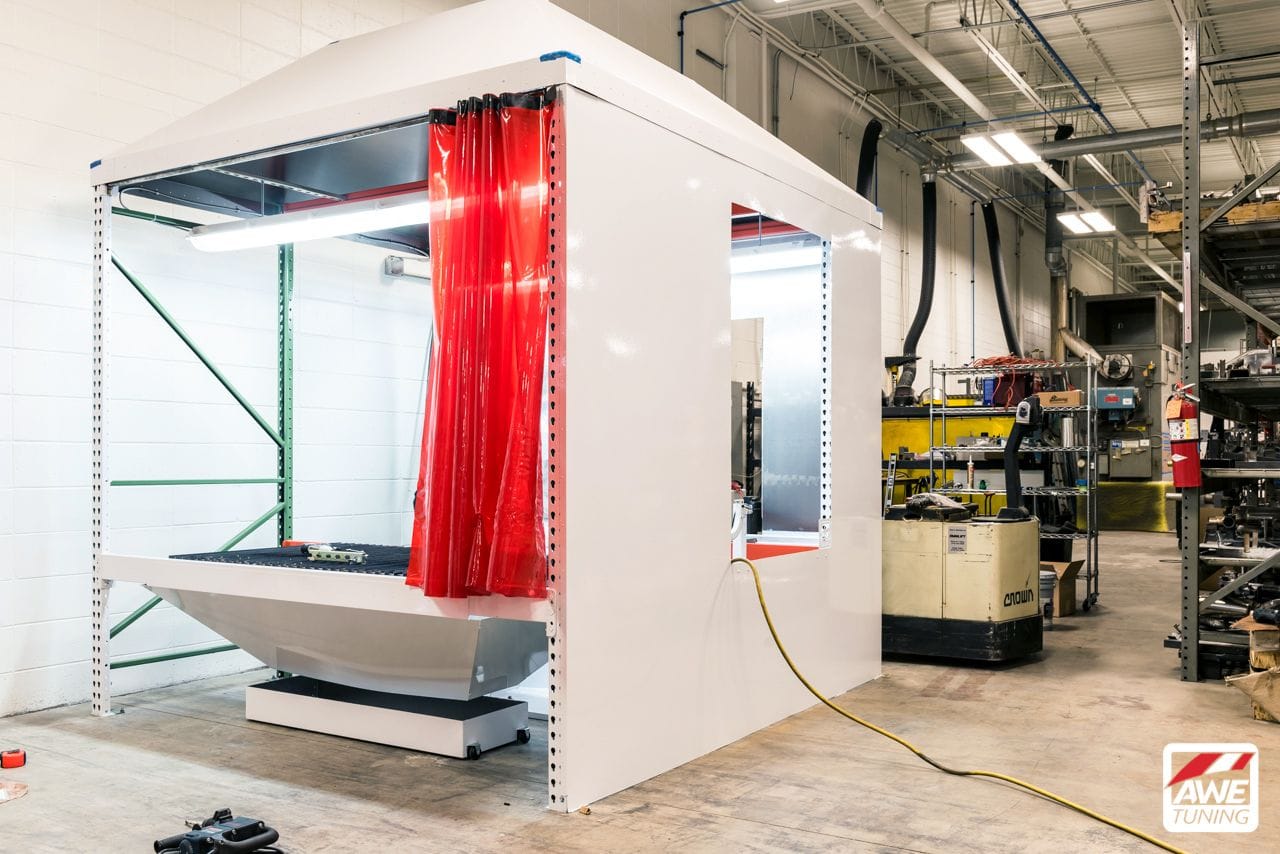

- The cell (which you’ll see evolve below) is designed to cut complex 3D shapes on mandrel-bent stainless steel tubing as well as flat sheet/plate metal (more engineering freedom for innovative designs)

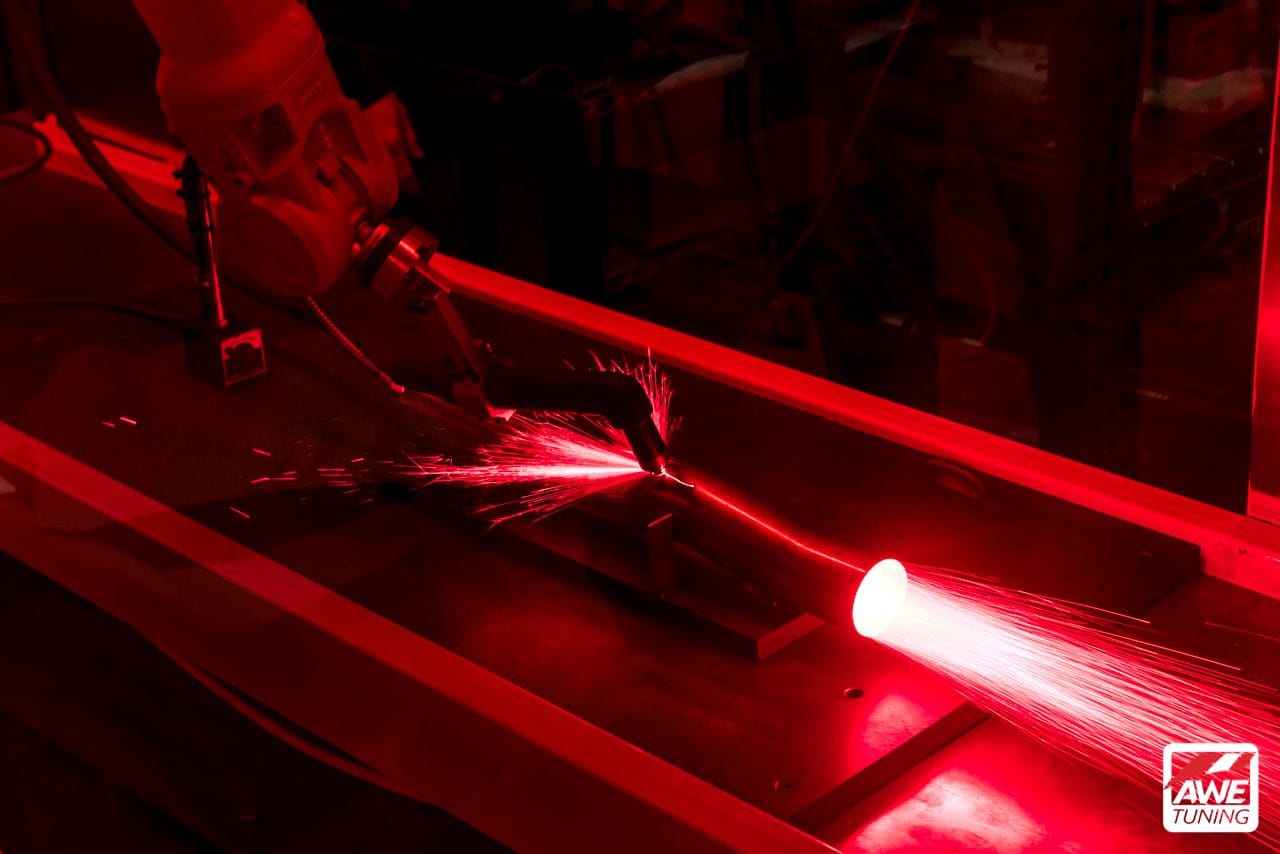

- The freedom of a 6-axis plasma cutter means we can cut the aforementioned material to our exact specifications (more accuracy)

- The beauty of non-contact cutting means the part does not need to be clamped to hold it in place (good looking outputs)

- Thanks to the specialized Hypertherm system and accompanying torch that the IRB wields, the cut quality is approaching that of a laser (better repeatability)

- We can prototype and iterate faster than ever before (future time savings)

Bringing it home:

X-pipes, which are featured in a number of our exhaust systems, would take eight minutes to cut on a mill. With the IRB that production is reduced by 98.6%, completing the cut in 6.6 seconds from start to finish. Wow.

Check out the inception of the AWE Tuning ABB IRB 1600 below and stay tuned for footage of it in action: