Things went back into the car super easy. Had some downpipe studs overnighted so I didn't have to deal with the old ones (surprised USP's turbo swap kit didn't come with any, though...). I also got some new bolts, one for the wastegate mounting amd one for the turbo support bracket (for obvious reasons). The bolts to the manifold are torqued surprisingly loose. The one thing that did give me trouble on the reinstall was the heat shield. It's simply hard to get to those bolts, and hard to figure out how the thing lines up.

Some concessions I noticed about my particular setup: 1) The compressor housing is clocked a bit too forward. The intake coupler (which is curiously from an older-style Uni DV relocation kit, when the rest of the kit is by CTS) really presses up against the vacuum lines.

2) My intake is much much smaller than the intake coupler. This is actually a good thing, because with the turbo clocked as forward as it is this is surely the only intake out there that would fit. The intake coupler fortunately doesn't buckle when it's tightened up to the intake, which also pulls it just barely away from the vacuum lines.

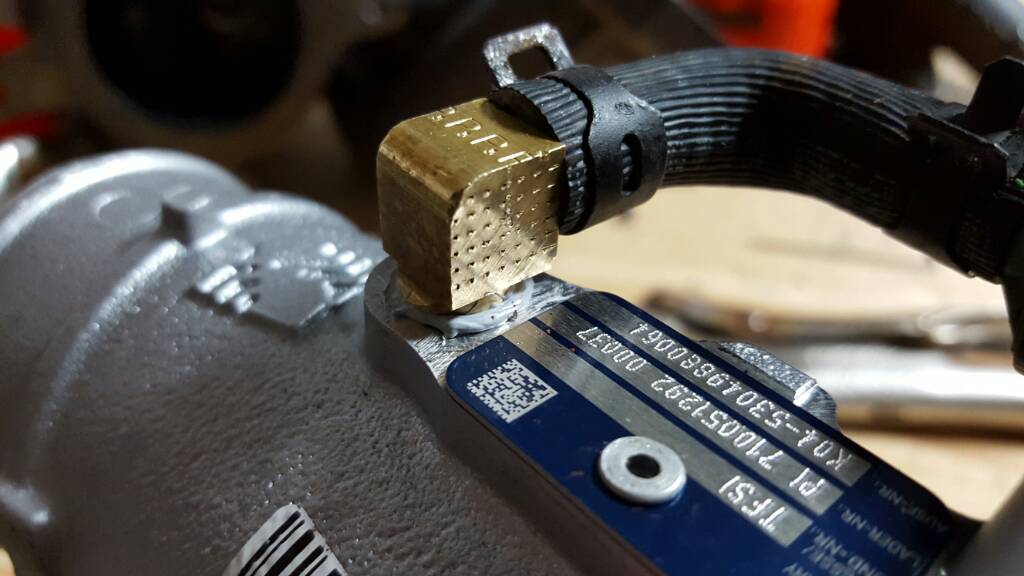

3) The N75 to Wastegate vacuum line is buckled in two locations. One is caused by pressing right up against the motor mount. The other is simply because it's too much of a bend in too little space. Now that the TOP is installed it's harder to see and get to, but I'm sure that it's not crimped to the point of cutting off the pressure to the wastegate.

Last issue was the coolant flush. As I noted above, the coolant lines were definitely not drained fully. At my buddy's recommendation I disconnected the coolant return line and let the electric pump drain out the rest of the coolant. Once it was drained I put a gallon of distilled water to try and cut out the old coolant. Once it drained clear I reinstalled the coolant return line and filled the reservoir with my 50/50 G12 and distilled water mix. And the system refused to draw the mix.

Turns out that the electric pump runs a separate circuit that includes the block and tirbo, but not the radiator. So because the radiator was full, the other circuit couldn't take on new coolant. This morning after the engine cooled I siphoned out about a gallon from the radiator through the return line (started the siphon only by squeezing the cold side radiator pipe - got to figure out why that worked), filled with more new coolant mix and it finally took. Only about a half a reservoir, though, so I'm somewhat concerned there may be air bubbles in the circuits somewhere. Driving to the shop didn't draw any additional coolant at any rate.

The car started right up the first time and I only got a couple minutes of smoke from behind the engine. After that the car drove great. Pretty normal behavior all the way to Team VW in Merrillville, IN. Only hit 3lbs boost max, though.